New sustainability solution for equipment manufacturers offers energy efficiency and data intelligence to create aftermarket revenue streams; XNRGY Climate Systems partners with Turntide for the development of a new energy-saving, intelligent cooling solution for data centers.

Turntide Technologies Launches Turntide for Strategic Machines™ Featuring The New TX Motor

Las Vegas - AHR Expo, Jan. 31, 2022 – Turntide Technologies (“Turntide”), developer of breakthrough technologies for electrification and sustainable operations, today announced the launch of Turntide for Strategic Machines™, a customizable full-stack hardware and software solution that improves energy efficiency and adds intelligence, controls, and automation to any commercial HVAC systems, pumps, and fans. Turntide now partners with original equipment manufacturers (OEMs) to integrate its Smart Motor System™ and transform its products into connected, data-driven machines that accelerate customer sustainability goals and create new service revenue streams.

Every business is under pressure to implement sustainability strategies with measurable impact. Commercial and industrial buildings account for 40 percent of electricity consumed globally and 20 percent of greenhouse gas emissions (GHG). HVAC energy consumption accounts for more than 40 percent of a commercial building‘s total energy use. Turntide for Strategic Machines can reduce HVAC energy use on average by 64 percent and smooth a path to more sustainable operations. than 40 percent of a commercial building‘s total energy use. Turntide for Strategic Machines can reduce HVAC energy use on average by 64 percent and smooth a path to more sustainable operations.

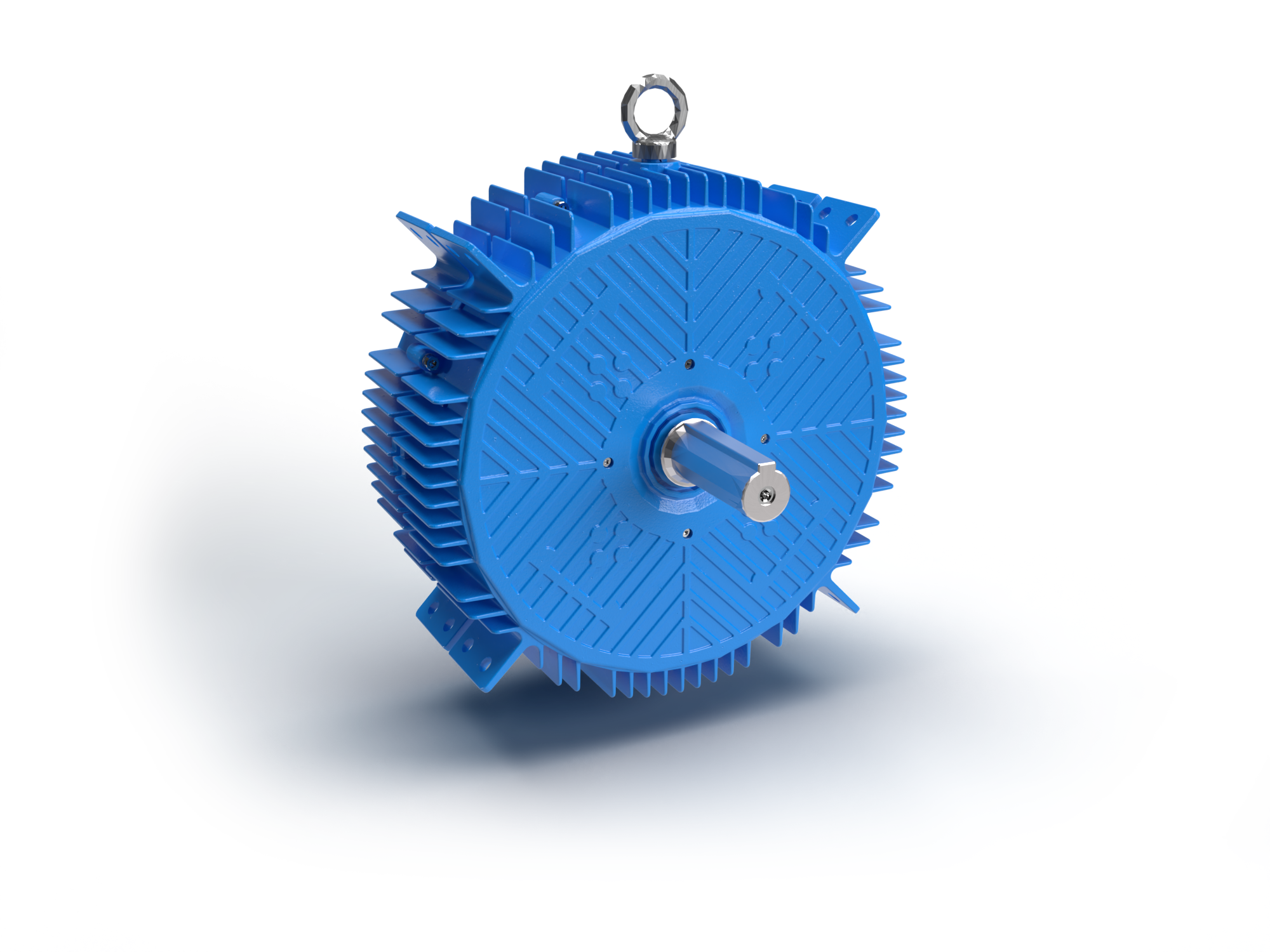

At the center of Turntide for Strategic Machines is the new TX motor. This intelligent motor features a unique pancake design that is 50 percent lighter than competitive models and is ideal for use in equipment with limited space and/or high torque requirements, such as axial fans in data centers. Its IoT capabilities enable automated commissioning, remote monitoring, and fault detection. Real-time data streams from the connected motor offer insights into equipment performance and present opportunities for new aftermarket recurring revenue streams, such as equipment-as-a-service subscriptions and condition-based service contracts.

OEMs can also use the data insights to accelerate product improvement timelines and bring more innovative products to market with a lower total cost of ownership and improved reliability

Turntide motors are free of the rare earth minerals that most high-efficiency permanent magnet motors require. Avoiding rare earths both reduces the environmental impact of the motors, as well as geopolitical supply chain risks.

Turntide is showcasing the Strategic Machines solution and the TX motor at the annual AHR Expo in Las Vegas at booth #N8535, January 31 - February 2, 2022.